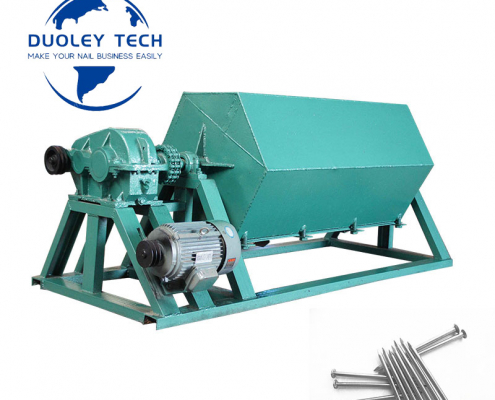

- Name: Nail polishing machine,

- nail washing machine

- Usage: Polishing nails to shinning, remove rust

- Capacity: we can make as clients demands.

- 400kg, 600kg,1000kg, 2000kg.

- Power: 3kw, 4kw, 5kw, 7kw.

- Size from small, middle, large.

Nail polishing machine is also called nail washing machine and polishing drums.

Duoley tech is a nail making machine manufacturer in China. Has own technical support in Africa, hope can set more support center in Africa.

A nail polishing machine is used to polishing common iron wire nails. It can make the surface smooth and shiny. After nail making machine cutting the nails making the wire, the punching pin punches the wire to shape the nail head. The nails will fall automatically, but with some oil or scraps in tips. In order to make it a bright and good-looking appearance, it needs a nail polishing machine’s help.

How to use nail polishing machine?

- Collect the origin fresh nails into the polishing machine or drums.

- Put some sawdust in the polishing drums.

- Seal the cover and fix the nuts and screws.

- Start polishing machine for 2 hours.

- Rechange the cover, replace the mesh door.

- Seal the mesh door and polishing.

- Polishing the nails for 1 hour till the sawdust comes out.

- Put some wax in the drums further, and then start polishing.

- After one or half-hour, then done.

A nail polishing machine is applied after nail making progress to polishing the nails made by the nail making machine. It removes the dark cover and oil on the nails and covers them with industrial wax to make the nails bright and smooth on the surface and prevent rusting. The advanced type, dismountable drum type, features fast nail loading and unloading.

Common type of nail polishing machine

| Model | Unit | DT-400 | DT-600 | DT-1000 |

| Capacity | kg | 400 | 600 | 1000 |

| Motor power | kw | 3-4 | 4 | 5.5-7.5 |

| Overall dimensions | mm | 1640× 900× 1000 | 1800 x 1000 x 1100 | 2000× 1500× 1400 |

More than nail polishing machine

One nail making machine and one polishing machine cant form a complete nail producing line. Now we got nail polished by nail polishing drums, and need more components. Such as wire drawing machine and grinding machine for cutting knives.

Furthermore, we can provide clients with various auxiliary equipment for nail making machines. Not only wire drawing machine, nail polishing machine but also spare parts. cutter die grinder, nail gripper dies, nail header dies, nail punch pin, nail cutter die, etc. Also, the wire drawing dies, and butt welding machine, and the wire pointing machine.

Reach us by email or whatsapp fur more details about nail making business.